Electric shock incident reiterates the need for testing and tagging

In an incident that should resonate with most employers, a hospital worker in Victoria received a severe electric shock when they touched a power cord which had damaged protective outer insulation.

WorkSafe Victoria, who investigated the matter, issued a safety alert given the widespread issue of the need for employers to test and tag electrical cords.

In this case, the power cord for the electric hospital bed had been damaged over time by the wheels of the bed which trailed along the floor during patient transfers.

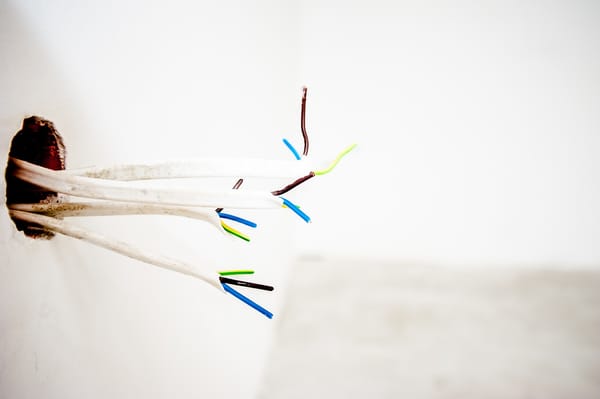

Due to the damage, electrical wires were exposed and when the worker plugged the cord into a power outlet, they received a large electric shock requiring immediate medical treatment. The worker had not noticed the damaged cord.

In the case of electric beds, WorkSafe Victoria has reminded employers of their duty to ensure that there are safe systems of work in place to stow cords when moving the beds and inspecting the cords before use.

Reference should also be made to industry standards, in this case the relevant Australian Standard AS/NZ 3200.2.38:1997 – Electrically Operated Hospital Beds.

Lessons for employers

Importantly, the risk of electric shock is one that all organisations must be conscious of, particularly if they have regular use or contact with electrically charged devices or equipment that have the potential to cause an electric shock.

Organisations, depending on the level of risk at the workplace, need to have in place a regular system of inspection and maintenance of electrical equipment, including testing and tagging.

Training of staff in detecting risks of damage to electrical equipment is also critical, so as to ensure that potentially unsafe environments are not left undetected.

From the experts behind the Health & Safety Handbook, the Bulletin brings you the latest work health and safety news, legal updates, case law and practical advice straight to your inbox every week.